9. After the luminous sign is installed, it needs to be put there for a night to dry before moving. Next, we start to make the bottom plate of the word shell, The big word of the bottom plate is welded with stainless steel plate, and the small word is white PVC; Here, the stainless steel plate baked white reflective paint as an example, the welding of the bottom plate and the welding of the shell panel process is the same, the painting process is the same; The white paint is sprayed for the effect of brightening the inner walls. With zinc plate bottom or stainless steel, large letters using aluminum plate bottom, relatively light, no matter what kind of material, as long as it is metal material, normal better point, because of its heat dissipation and cold resistance, especially in the outdoor weather resistance.

10. The luminous sign bottom plate is followed by the row of lights, also known as the installation of lights; We usually install LED modules, if it is indoor signs can also use light belts. Most outdoor light signs require to use of a certain waterproof level of LED modules. There is 3M adhesive on the back of the module, which is evenly pasted on the base plate and then affixed with white glass adhesive to fix it. Double-sided adhesive generally plays a temporary fixing role, while structural adhesive or glass adhesive plays a long-term sealing and fixing role. Especially in the outdoor light signs without glue is not allowed.

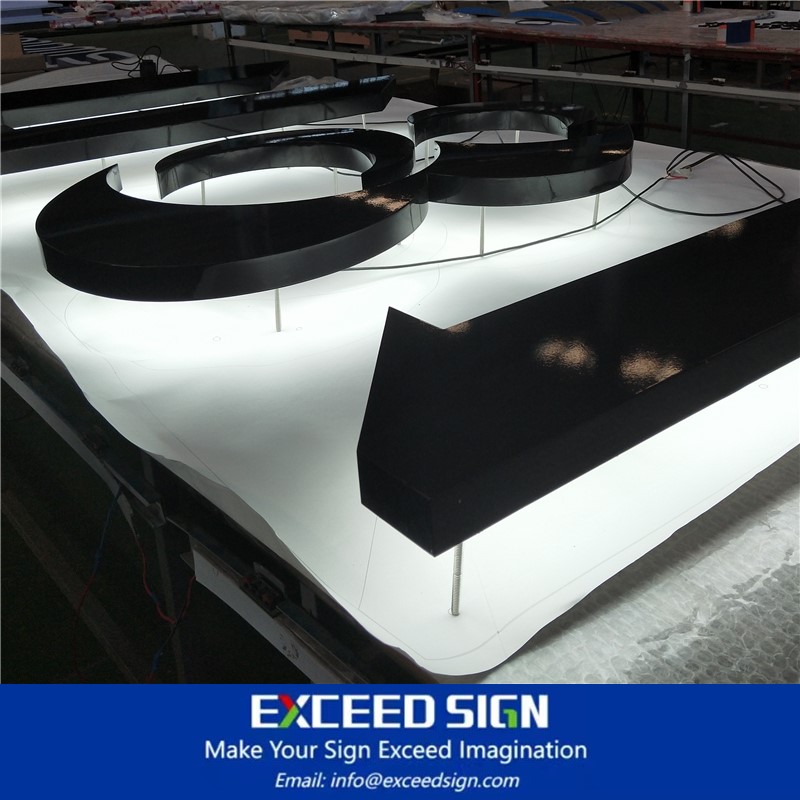

11. Test light, light sign test light this step can also be called dimming; The uneven place will be adjusted evenly, and the position that is not bright will be lit. At the same time, the line between the LED module and the module of the luminous sign needs to be pressed down; In case of blocking the light.

12. After the light sign test light is completed, it is assembled; The luminous sign shell and the luminous sign bottom plate are fixed with gong wire, Under normal circumstances, what color the shell is, what color the screw is to use; Otherwise, it seems incongruous. You also need to use stainless steel screws.

13. After the assembly of the luminous sign is completed, it is necessary to copy the word; In the light sign production factory this link is essential, a set of light signs must have a lot of strokes. Need to print the installation to check whether the luminous sign is complete.

14 light sign proofreading after the need for bubble film packaging, light word surface protection is the last step before the factory, bubble film wrapped need to be shipped in wooden boxes if the light sign is larger in the case of welding iron frame delivery, such as a pylon or gas station.

15. Delivery from factory.

Exceed Sign Make Your Sign Exceed Imagination.

Post time: Aug-17-2023