The use of signs has been a source since ancient times, such as the small boards hanging in front of many shops in ancient times can be counted as a sign. Now with the continuous progress of industrial technology, sign production has more ways to present, according to the statistical data can be seen that aluminum plate sign is a very popular type of sign, then aluminum plate sign production needs what process?

1. Degreasing and polishing process

The good quality sign companies said that the aluminum plate material needs to be painted before it is processed and made, and the production can be mass-produced after the uniform size. After the painting is completed, oil removal can be carried out. The main purpose of oil removal is to reduce the oil content on the surface of the aluminum plate so that the material has a certain affinity for printing paint. The material used for oil removal is determined by the oil stain on the surface of the aluminum plate. Therefore, to achieve a better oil removal effect, we must first understand the source and type of oil content on the surface of the aluminum plate.

After the oil removal is completed, the polishing process can be carried out. The main purpose of polishing is to increase the gloss of the surface of the aluminum plate. At the same time, the scratches on the surface of the aluminum plate should be scraped with putty to make it more smooth.

2. Spray painting and printing process

After the above process, the aluminum plate has become a very flat surface with no excess oil, so you can start the painting process. The role of the primer is to enhance the adhesion between the aluminum plate and the top paint, and the color of the top paint needs to be selected according to the needs of customers, at the same time, when processing the top paint, especially the light color of the top paint must pay attention to the drying temperature and drying time to prevent the top paint from yellow. After the completion of the painting process, you can begin to print, the key points of the printing of the sign are the accurate position of the text and cleaning, the edge of the word line is neat and the ink is firm.

The above steps are very critical in the overall process of signage production, whether it is from the early oil removal and polishing or the later painting and printing, it is necessary to pay attention to accidents in the process. For example, when spraying the top paint, it is necessary to pay attention to the drying time and temperature, otherwise, it will cause the yellow paint to affect the overall effect of the sign.

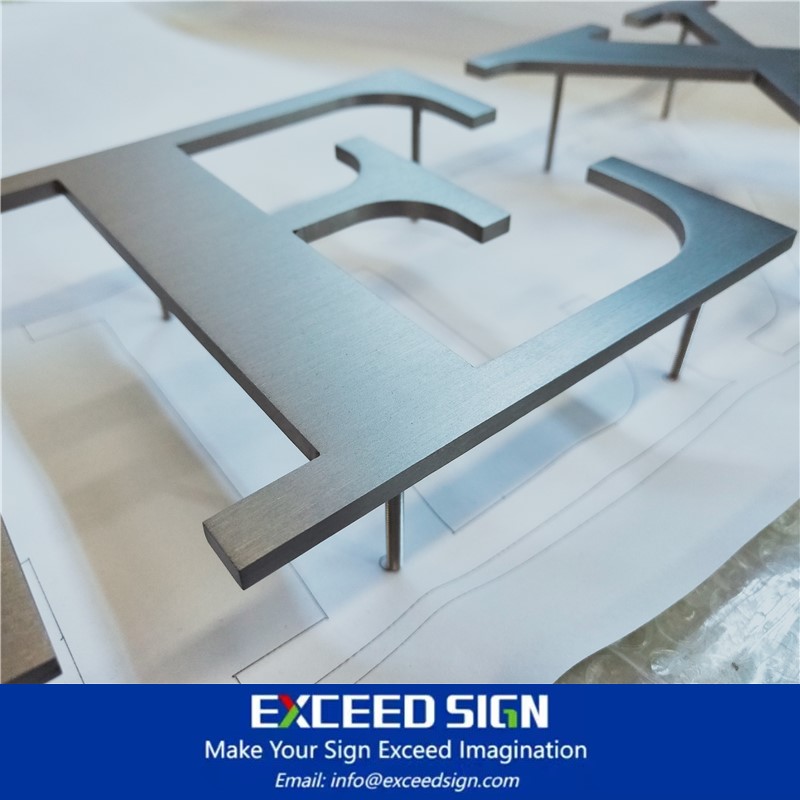

Exceed Sign Make Your Sign Exceed Imagination.

Post time: Nov-06-2023